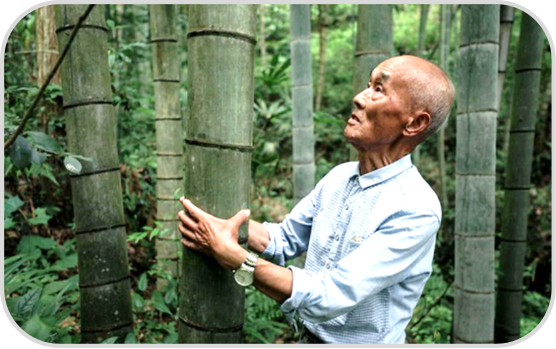

1. Bamboo Selection

Selecting the bamboo over 4-6 years old.

2. Bamboo Harvest

Cutting the selected bamboo down.

3.Transportation

Transporting the bamboo from the forest to our factory.

4. Cutting Bamboo

Cutting the bamboo in a certain length according to their diameters.

5. Bamboo Splitting

Splitting the bamboo poles into strips.

6. Rough Planing

Planing the bamboo strips roughly by machine.

7. Carbonization

In the carbonization oven, under high temperature and high pressure to remove bacteria, worm eggs and suger, also make the bamboo stronger.

8. Bamboo Strip Drying

Drying the bamboo strips to control the moisture content between 8% ~ 12%.

9. Bamboo Strip Polishing

Polished by this machine to make the strips smooth.

10. Machine Color Classification

Using the color picking machine to classify the bamboo strips to make sure the color of each bamboo board be consistent.

11. Manual Color Classification

In order to ensure the quality of each bamboo board, will take manual color classification again.

12. Pressing Bamboo Plywood

Pressing the strips into bamboo plywood (board).

13. Let It Rest (Health Care)

After hot pressing, it needs a certain time for the plywood to rest. This step is critical. Sufficient storage (rest) time can prevent bamboo products crack. It’s a magic process.

14. Bamboo Plywood Cutting

Cutting the bamboo board to different sizes according to different products and different uses.

15. CNC Machine

By CNC mahcine, making products in many different shapes according to the computer drawings.

16. Assembling

Many of our workers have at least 5 years of bamboo product processing experience and which can ensure the efficience and good quality.

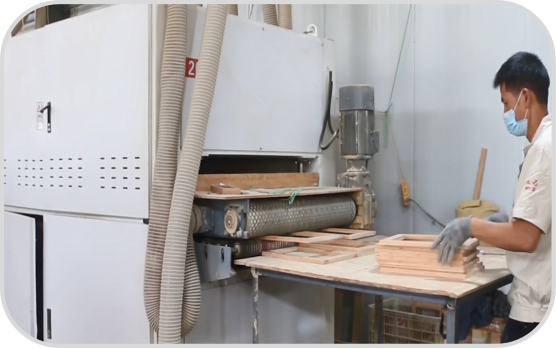

17. Machine Sanding

First sanding is by machine to make the product’s surface smooth.

18. Hand Sanding

Second sanding is by hand to ensure the quality of the product.

19. Laser LOGO

With this machine, you can customize your own brand logo on the products.

20. Painting

We have 4 automatic painting lines to ensure that your order is completed quickly and with high quality.

21. Quality Inspection

Quality control is not only after the products finished, but also during the whole production processes.